Why Use Finite Element Analysis (FEA)

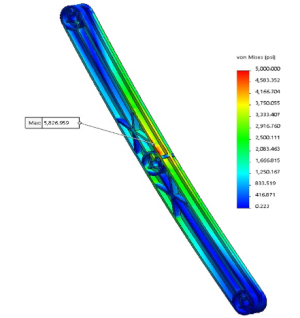

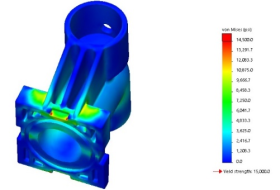

The application of FEA simulation is a commonly used and effective method for helping to solve problems, optimize designs and identify potential design concerns. Typical areas of interest include structural analysis, stress levels, factor of safety and deflection.

Using FEA simulation as a tool during the early design phase can;

- Reduce the number of iterations

- Help optimize the design

- Greatly enhance the prototyping process and final design

- Decrease final product cost.

Using FEA simulation as a problem resolution tool it can;

- Quickly identify high stress points

- Locate areas of excessive deflection

- Help identify areas that exceed the material mechanical properties

What Mondek Solutions Can Offer You

- Provide FEA and design experience to support your design team

- Help define boundary conditions and loading parameters

- Import numerous client file format types to facilitate analysis, if 3D models are not available then we can translate your 2D drawings into a 3D format

Conduct static linear analysis to;

Conduct static linear analysis to;

- Facilitate design optimization

- Determine potential areas of failure due to high stress/deformation

- Identify factor of safety

- Etc.

- Alter model in real time to achieve required results. This includes geometric and material alterations

- Provide detailed, all-inclusive reports including stress, strain, deflection, safety factor, highlighting results, provide recommendations and identify suggested follow up work

For more information about how we can help you, or to begin any of the services mentioned above, contact us at 855-282-4867 or at info@mondeksolutions.com